The Best 3D Printer for Jewelry

The ancient craft of jewelry making can

now be done with technology through 3D printing. It enables designers and

manufacturers to produce beautiful, unique and intricate designs that used to

take weeks or a month for a goldsmith or jewelry maker to create. 3D printing

usually applies in making prototypes but has now moved into manufacturing finished jewelry.

Designers and prototype jewelry makers are able to save time and money with the

use of the new technology. It is a cost efficient method of creating plastic

prototypes of jewelry before these are sent for final design and production.

Independent jewelers can actually use it in making the final design in metal.

Unfortunately, a 3D metal printer is still very expensive but in the future this is going to be a viable option for jewelry creation. Most independent

jewelers use 3D printing services with a wide range of metal material such as

gold, silver and platinum.

The ancient craft of jewelry making can

now be done with technology through 3D printing. It enables designers and

manufacturers to produce beautiful, unique and intricate designs that used to

take weeks or a month for a goldsmith or jewelry maker to create. 3D printing

usually applies in making prototypes but has now moved into manufacturing finished jewelry.

Designers and prototype jewelry makers are able to save time and money with the

use of the new technology. It is a cost efficient method of creating plastic

prototypes of jewelry before these are sent for final design and production.

Independent jewelers can actually use it in making the final design in metal.

Unfortunately, a 3D metal printer is still very expensive but in the future this is going to be a viable option for jewelry creation. Most independent

jewelers use 3D printing services with a wide range of metal material such as

gold, silver and platinum.

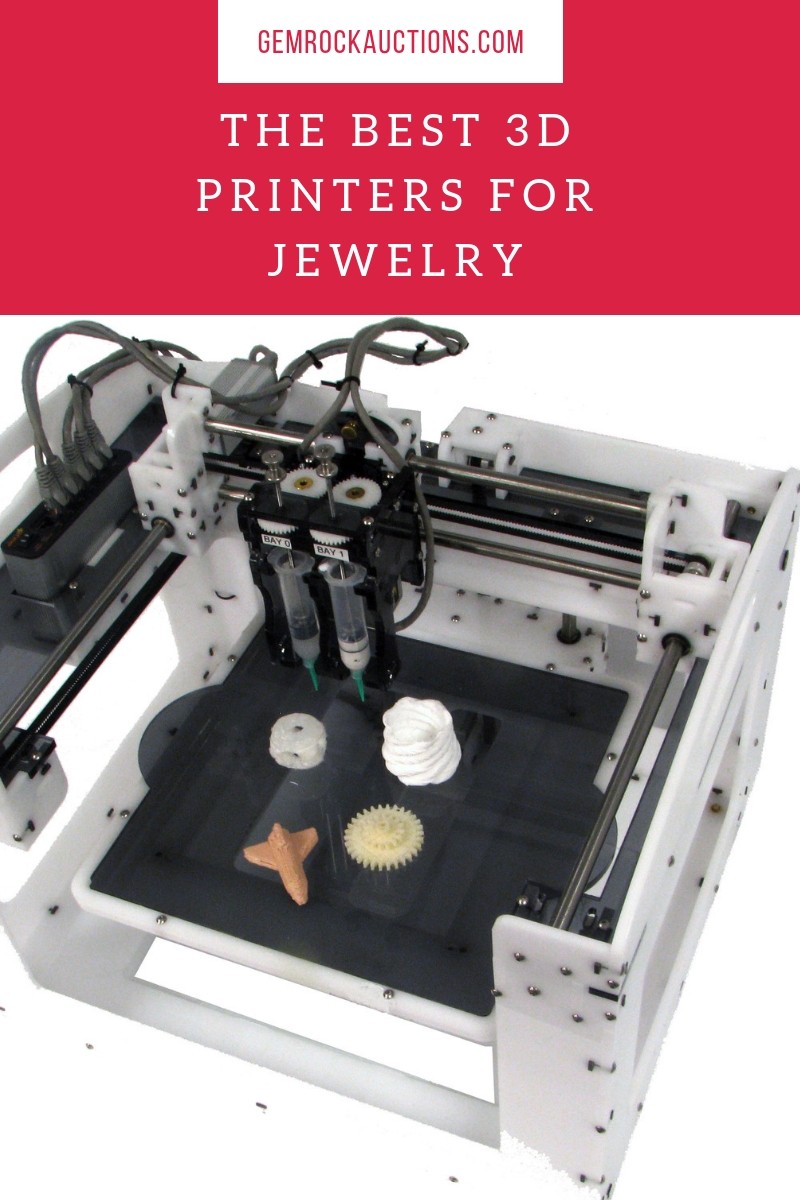

Types Of 3D Jewelry Printers

There are 2 types of printers for jewelry making: FDM and SLA filament. Each one can make perfect mold casts.

- FDM or Fused Deposition Modeling is a printing method using a sustained filament of thermoplastic material that’s fed through a movable and heated printer extruder head. Heated and melted material comes out of the printer head to shape and mold the printed piece. FDM has the ability to mix plastic and metallic filaments to create a semi metallic jewelry. It is the most cost efficient method of producing prototypes and in the actual manufacturing of jewelry with simple design specs. Prices for the FDM printer start at $1,000.00, where independent jewelry makers and hobbyists can easily afford to buy one. And software and solutions are readily available online through open sources.

- SLA or Stereolithography apparatus, also known as optical fabrication photo-solidification or resin printing uses the method of producing parts in a layered process using photopolymerization. In this technique, light generates molecules to link forming polymers. The polymers create the body of a 3D solid object. It has the ability to create prototypes with precise and elaborate designs with precious stone or gem settings. SLA has the advantage of integrating investment casting and home 3D printing especially with gem settings. The castable resin in SLA does not stain once liquefied and results in high quality jewelry all the time.

3D Jewelry Printers In Actions

3D Wax Printing

Printing Direct To Metal

FDM and SLA are the best 3D printers for jewelry, making it faster and easier to design and make custom jewelries. These are also used for repairing damaged jewelry or in changing settings as desired by customers. Independent jewelry makers can easily accommodate customers’ specifications without compromising on time and quality.

SHOP FOR JEWELRY

Was this article helpful?

4 people found this article helpful

Gem Rock Auctions

- Written - 27th Sep 2018

- Edited - 1st Aug 2023